Bean to Bar machine: the first compact machine for making chocolate is created

Domori, leader of gourmet chocolate production, and Tecno3, a leader in machine manufacturing and of the confectionary industry, are launching the first compact Bean to Bar machine, a completely new technology in the chocolate and pastry industries.

Small in size, but large in technological heart, the Bean to Bar Multiprocess machine is the first compact system for producing chocolate from the cocoa nibs to the bar. It offers a world of new opportunities to maitres chocolatier, patisseries, and international retailers.

“We had been looking for an innovation that would open new horizons in fine chocolate consumption,” says Jean Pierre Willemsen, CEO of Domori. “Now with this machine, which is highly precise and technological, Domori’s constant pursuit of the best raw ingredients will be at the disposal of chocolatiers all over the world, offering consumers the chance to personalize their own chocolate bars in both type and form.”

Just 2 x 1 meters in size, the machine can be completely dismounted for quick and easy cleaning. Multiprocess can be displayed in-store to allow customers to watch the fascinating process of creating chocolate, while conserving the high quality, aromas, and inimitable characteristics of the most noble cacao during all phases of production.

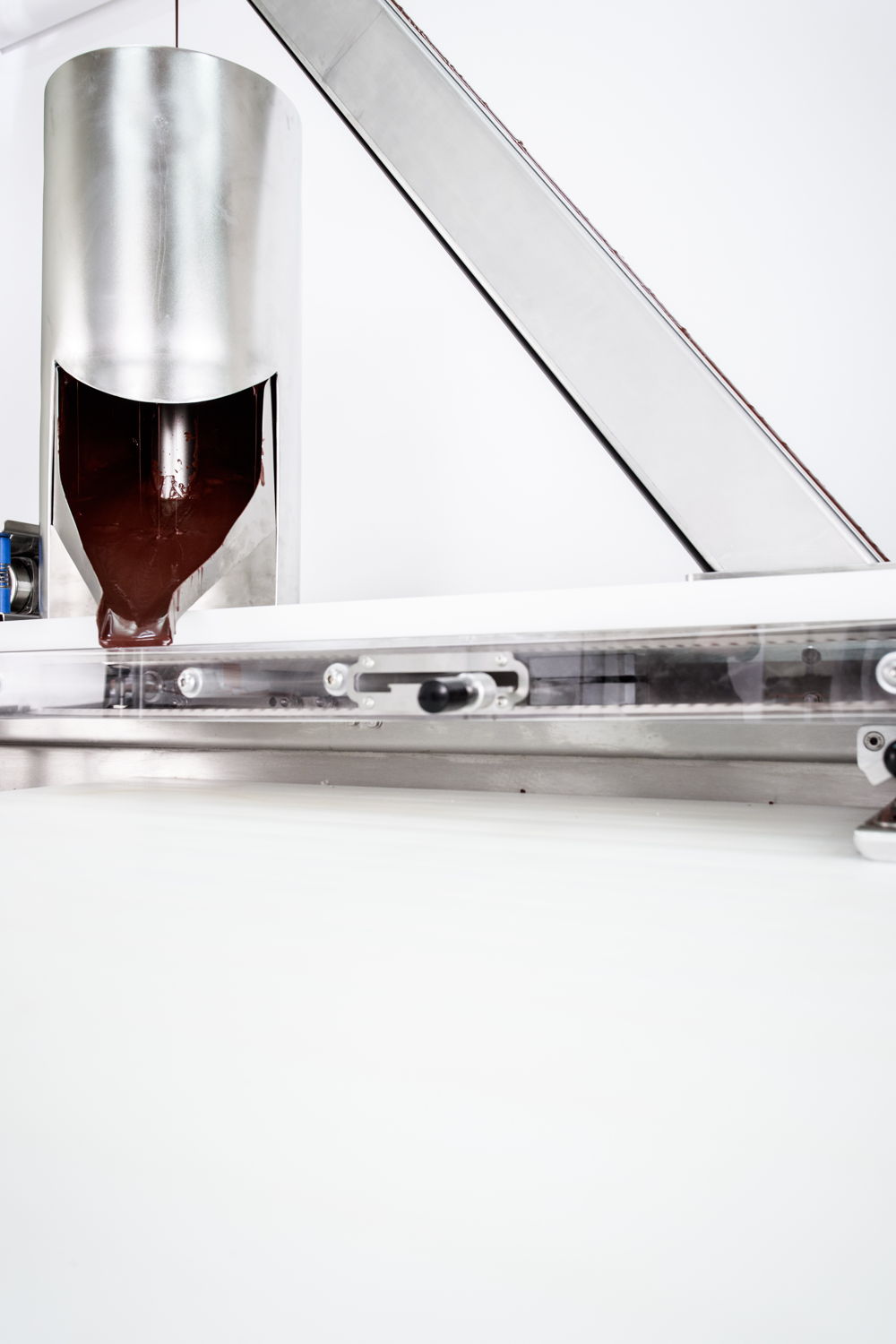

Every step is easily managed with a touchscreen command panel that is both simple and intuitive: Domori cacao nibs are placed in the container and transformed into cocoa mass, then mixed with other primary ingredients. The paste is then refined and transferred along a viewable belt to the innovative phase of conching, which eliminates excessive acidity.

The continuous cycle lasts about two hours and operates at a low energy level (7 kW), allowing a final chocolate with a fineness of about 18 microns. At this point, after being finely sieved and tempered, the produced is ready to be molded as desired and is then left to rest in an integrated refrigerated unit below the process area.

“Bean to Bar Multiprocess is the most technologically advanced machine for working with cacao that still respects the traditional production process using high quality ingredients,” says Bruno Porro, owner of Tecno3. “The production process is simple and automated. It completely respects the qualities and aromatic notes that are naturally present in the best varieties of cacao. It’s for this reason that it’s fundamental to use only the most noble cacao varieties, to be able to maximize the potential of this machine and create such unique chocolate.”

The cocoa nibs come from the Domori factory at None in the province of Torino. Here the raw cacao beans undergo debacterization before being gently toasted. This enriches the aromatic bouquet that develops during the fermentation phase. Next, the beans are crushed and the husks are separated from the cocoa nibs.

This delicate and careful process keeps the natural essences of the beans’ unique origins intact.

The assortment of Domori cacao nibs for use in the Bean to Bar machine are available as 5 kg bags and include:

PERÙ - CACAO TRINITARIO - APURIMAC

Notes of flowers, caramel, and cream. Very delicate with subtle acidity.

ECUADOR - CACAO NACIONAL - ARRIBA HACIENDA VICTORIA

Hacienda Victoria is extraordinary in their vision to cultivate three pure clones of the Nacional cacao, showing extreme elegance and a note of pure white flowers.

TANZANIA - CACAO TRINITARIO - MOROGORO

Decisive character and aromatic profile with immediate primary notes of cacao, spices, and wood.

VENEZUELA - CACAO TRINITARIO - SUR DEL LAGO

Notes of almond and coffee. Very fine, round, and persistent.

MADAGASCAR - CACAO TRINITARIO - SAMBIRANO

Notes of red fruit accompanied by a pleasant acidity. Sweet and round with good persistence.

VENEZUELA - HACIENDA SAN JOSÈ - CACAO CRIOLLO

A unique sensory experience. Perfect balance and persistence. Endless aromatic nuances. Extraordinary elegance.